Search By Department

- Access Control

- Time And Attendance

- VDO Gauges

- Marine Gauges

- Industrial Gauges

- Senders & Switches

- Meter Systems

- Automotive Equipment

- Tools

- Door Controllers

- Biometric Hotel Doors

- CCTV Access Control

- Electronic Components

- Fingerprint Readers

- Facial Recognition

- MultiBio Readers

- Clocking Machines

- JOB Costers

- ALL Warn Winches

- High Lift Jacks

- More Categories Collapse

Download Our VDO Gauges Catalogue

Process Industry Use Pressure Gauges

Industrial Pressure Gauge - PROCESS GAUGE

Heavy duty gauge intended for the process industry such as the chemical, petro-chemical, energy, oil & gas and the food and beverage industry. Glycerine fillable.

- 63, 80, 100, 160, 250mm dial

- S/steel case and bayonet bezel

- Brass or s/steel 316 wetted parts

- 1/8, 1/4, 3/8, 1/2" BSP/NPT Bottom or rear connection. Panel or surface mount flange optional

- -100...0...160MPa, bar, psi etc.

- Accuracy 1.0% and 1.6% F.S.

Service Intended

Suitable for media such as air, water, oil & gases that do not attack copper alloy or stainless steel parts or will obstruct the pressure system. Typical applications will be in the hydraulic, pneumatic, refrigeration, steam, chemical and food and beverage industry.

Case Details

Nominal Dia: 63, 100, 160, 250mm Material: Stainless steel 304

Bezel

Bayonet lock, twist type - removable. Material: Stainless steel 304

Pressure Connections

Material: Type T3: Brass. Type T4: Stainless steel 316

Sizes: 63 mm dia: 1/8” & 1/4” in BSP or NPT

Sizes: 100, 160 mm dia: 1/4”, 3/8” & 1/2” in BSP or NPT

Position: See “Mounting Configurations”.

Mounting Flange

Material: Polished stainless steel 304

Position: See “Mounting Configurations”.

Pressure Element

Material: Type T3: Cu-alloy Type T4: Stainless steel 316

Geared Movement

Material: Clockwork brass or stainless steel.

Pointer

Collet: Aluminium or brass

Blade: Black aluminium

Dial

Material: Aluminium, white with black lettering.

Window

Instrument glass, plexiglass or safety glass.

( Plexiglass recommended for food applications )

Weather Protection

IP 65 Dust & weather proof.

Working Pressure

Steady: Full scale value

Fluctuating: 90% of full scale value

Short Period: 130% of full scale value

For pulsating pressure, the use of an inlet restrictor and/or liquid

filling is recommended.

Accuracy Class

63mm dia: Class 1.6

100mm, 160mm & 250mm dia: Class 1

Operating Temperature

Ambient: -20 °C to + 60 °C

Medium: +70 °C ( soldered tube ): + 100 °C ( brazed / tig

wellded tube ) For live steam use, a syphon tube is

recommended.

Optional Extras

Calibration Certificate

Customized scale plates ( customer logo, red line, etc )

Special Dials, other than standard ( dual scale, bar, psi )

Damped movement ( Vibragauge )

Single or double electrical contacts

Colour Coding of dial

Drag pointer ( maximum set pointer )

Micro adjustable pointer

Diaphragm seals fitted

Industrial Pressure Gauge - PROCESS GAUGE

Heavy duty gauge intended for the process industry such as the chemical, petro-chemical, energy, oil & gas and the food and beverage industry. Glycerine fillable.

- 63, 80, 100, 160, 250mm dial

- S/steel case and bayonet bezel

- Brass or s/steel 316 wetted parts

- 1/8, 1/4, 3/8, 1/2" BSP/NPT Bottom or rear connection. Panel or surface mount flange optional

- -100...0...160MPa, bar, psi etc.

- Accuracy 1.0% and 1.6% F.S.

Service Intended

Suitable for media such as air, water, oil & gases that do not attack copper alloy or stainless steel parts or will obstruct the pressure system. Typical applications will be in the hydraulic, pneumatic, refrigeration, steam, chemical and food and beverage industry.

Related Products

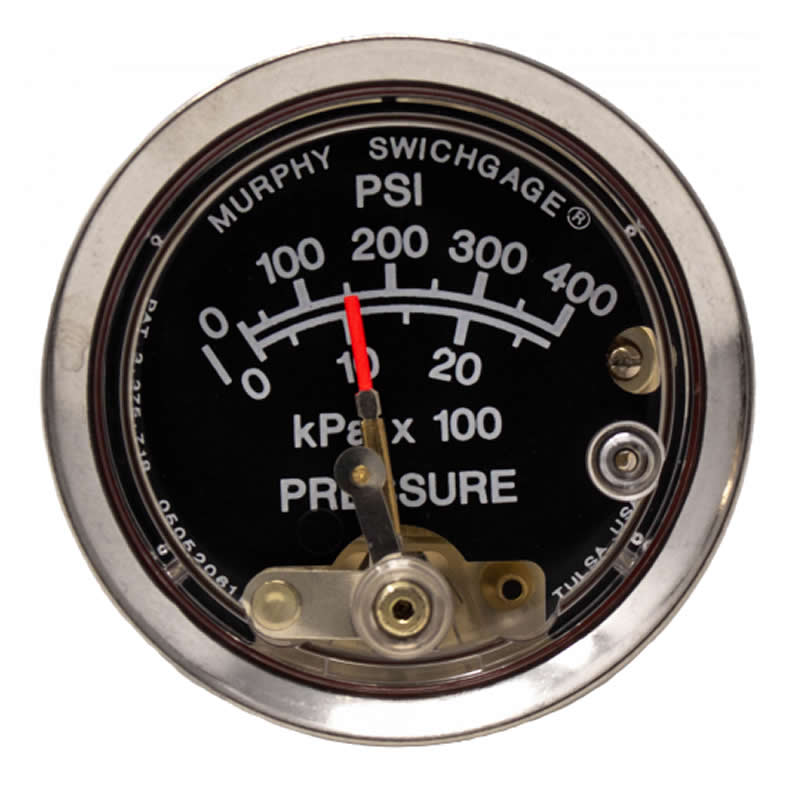

Murphy Pressure Mechanical Gauge

Industrial Pressure Gauges

Murphy Differential Pressure Gauge

Industrial Pressure Gauges

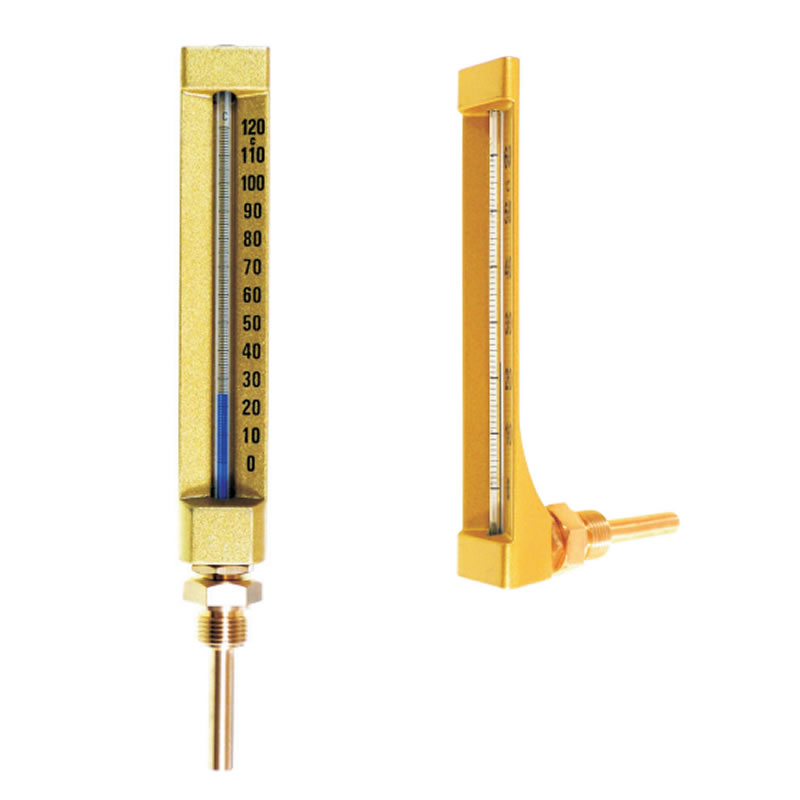

Murphy Temperature Gauge (160-320F)

Industrial Temperature Gauges

Murphy Temperature Switchgauge

Industrial Temperature Gauge

Tyre Pressure Industrial Gauge

Pressure Gauges

Pressure Transmitter

Pressure Gauges

Pressure Testing Kits

Pressure Gauges

PD8100 Series - Pressure Sensors and Instruments

Pressure Sensors and Instruments

Medical Infrared Thermometer

Temperature Gauges

Our Automotive and auto electrical products include: automotive Cables, automotive Cameras, auto electrical Central Locking, automotive Gauges, Ignition, auto electrical Lamps, Engine Monitors, Sensors, Switches & Senders, Tachographs, VDO Gauges & Equipment, Test Equipment, Windscreen Washers Components, Industrial Gauges, Rev Counters & AutoMeter, Murphy Gauges, Vision Range LED Lights, VDO GAUGES, MARINE GAUGES, SWITCHES & SENDERS, HIGH LIFT JACK, SPEEDOMETERS, SHOCK ABSORBERS, WARN WINCHES, INDUSTRIAL GAUGES, and VISION LED LIGHTS.

- Address (Johannesburg Head Office): 23 Stevens Rd, Blairgowrie, Randburg, South Africa, 2194

- Cape Town Branch: 3 Bank Road, Fishhoek, Cape Town, South Africa

- Call Us: 011 326 4146

- Email: adriang@lantic.net

Information